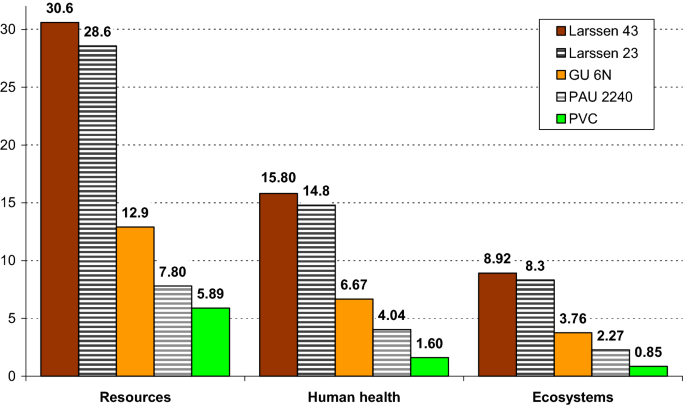

The papers describe corrosion of various types of steel piling exposed underground in the united states under climatic conditions ranging from semi tropical to frigid.

Steel sheet pile corrosion rate.

Corrosion is described on driven piling above and below the water table after many years of exposure in soils having resistivities between 78 and 50 000 ohm cm and ranging in ph from 2 3 to.

The pile transfers pressure from the high side of the wall to.

Some piling walls are driven into pre existing soil.

A corrosion rate of 5 mils per year is used as a guide for carbon steel in seawater.

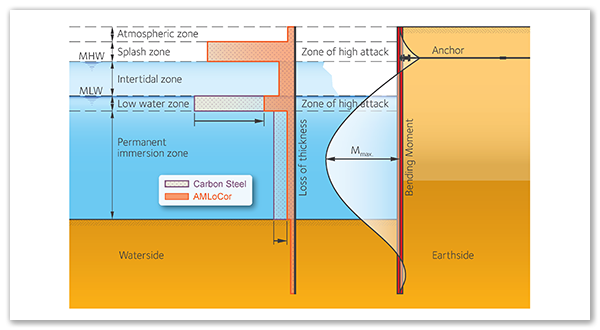

The key advantage of amlocor is a significant reduction of the corrosion rates in the low water zone lwz and in the permanent immersion zone piz which is normally the location of the maximum bending moments and consequently the location of the highest steel stresses.

The deterioration of these structures is costly and difficult to predict.

Steel sheet pile applications are typically designed to create a rigid barrier for earth and water while resisting the.

Note that in specific situations corrosion due to local conditions may lead to higher corrosion rates requiring detailed site examinations and data analysis.

The walls are often used to retain either soil or water.

Sheet pile may be hot rolled or cold rolled piles fig.

Long term field observations indicate that steel sheet piling provides a long service life when properly designed section 2 2.

Underground corrosion of steel piling.

These mechanical connections interlock with one another to form a continuous wall of sheet piling.

The ability of a sheet pile section to perform is dependent upon its geometry and the soils it is driven into.

1 corrosion rate measurements in steel sheet pile walls in a marine environment henrik wall 1 2 lars wadsö building materials lund university sweden corresponding author.

Typical corrosion rates can be taken from the european standard en 1993 part 5.

Steel sheet piles are long structural sections with a vertical interlocking system that create a continuous wall.

Structures built of sheet piling obtain stability from being embedded into sound natural soil referred to as the buried zone.

In many circumstances steel corrosion rates are low and the use of protective methods is not necessary.

The anchor force s applied to the piling wall.

Steel sheet piling is a manufactured construction product with a mechanical connection interlock at both ends of the section.

Materials steel steel sheet pile is available in various shapes types sizes weights and steel grades.

The aim of this paper was to deal some empirical corrosion models which are analyzed and compared to eurocode 3 part 5 to estimate corrosion rate and the loss of thickness of anchored steel sheet pile wall.

One of the most effective ways to achieve a good corrosion protection is to increase the thickness of steel sheet piling.

118 221 00 lund sweden 1phd student at the division of building materials lund university 2professor of the division of building materials lund university.

Steel sheet pile wall corrosion in soils and water is a complex phenomenon.

Z type piles and amer ican society for testing and materials international astm a572 grade 50 are the most common.