Heat treating aisi 301 stainless steel aisi 301 stainless steel is delivered in pre tempered condition and no further hardening can be achieved via heat treating.

Stainless steel 301 sheet metal heat treatment.

Heat treatment stainless steel grade 301 is subjected to solution treatment annealing in temperatures ranging from 1010oc to 1120 c followed by rapid cooling.

Heat treaters are tasked with developing the right balance.

Use it for high pressure applications in caustic environments.

276 is a family of iron based alloys that contain a minimum of approximately 11 chromium.

Also known as duplex stainless steel it has twice the strength of 316 stainless steel.

For intermediate annealing a low temperature range is chosen.

Its work hardening rate is extremely high with each increase in the amount of cold work the tensile strength and yield strength will increase significantly.

Paper sheets corrugated plastic sheets corrugated sheets cotton drop sheets cubed foam sheets damper convertible low carbon steel sheets decorative metal sheets drop sheets dry erase sheets e glass.

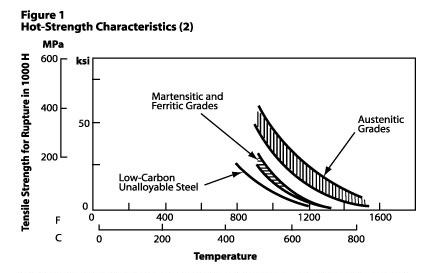

The most common stainless steels are divided into four main classes.

Stainless steel 301 is a commonly available austenitic stainless steel with good corrosion resistance and elevated carbon to allow for cold working to a variety of tempers.

2205 stainless steel resists cracking even when faced with a combination of tensile stress corrosive chemicals and heat.

However depending on the needs of your application completed flat springs and sheet metal stampings will undergo a stress relieving process.

301 stainless steel 1 type 301 is an austenitic chromium nickel stainless steel that provides high strength and good ductility when cold worked.

3 different types of stainless steel include the elements carbon from 0 03 to greater than 1 00 nitrogen aluminium silicon sulfur titanium nickel copper selenium niobium.

Grade 301 stainless steel is highly ductile for formed products.

3 a composition that prevents the iron from rusting as well as providing heat resistant properties.

Aisi 301 stainless steel uns s30100 is the most susceptible to cold deformation strengthening among conventional austenitic stainless steels.

Types of stainless steel.

Heat treatment methods such as stress relieving hardening and annealing strengthen the ductility and corrosion resistance properties of the metal that is modified during fabrication or generate hard structures capable of.

Stainless steels are generally heat treated based on the stainless steel type and reasons for carrying out the treatment.

Thermal hardening does not suit this grade of stainless steel.

It is a modification of type 304 in which the chromium and nickel contents are lowered to increase the cold work hardening range.

Balance is achieved when heat treating and annealing stainless steel parts is precisely matched to their makeup and intended use.

.jpg)