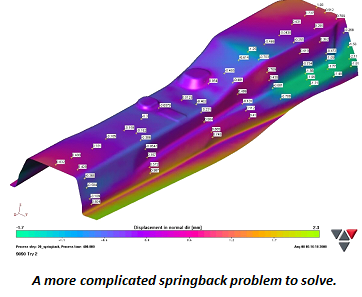

Upon completion of sheet metal forming deep drawn and stretch drawn parts spring back and thereby affect the dimensional accuracy of a finished part.

Springback sheet metal degrees.

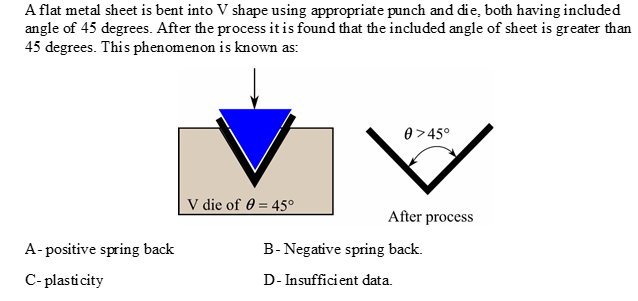

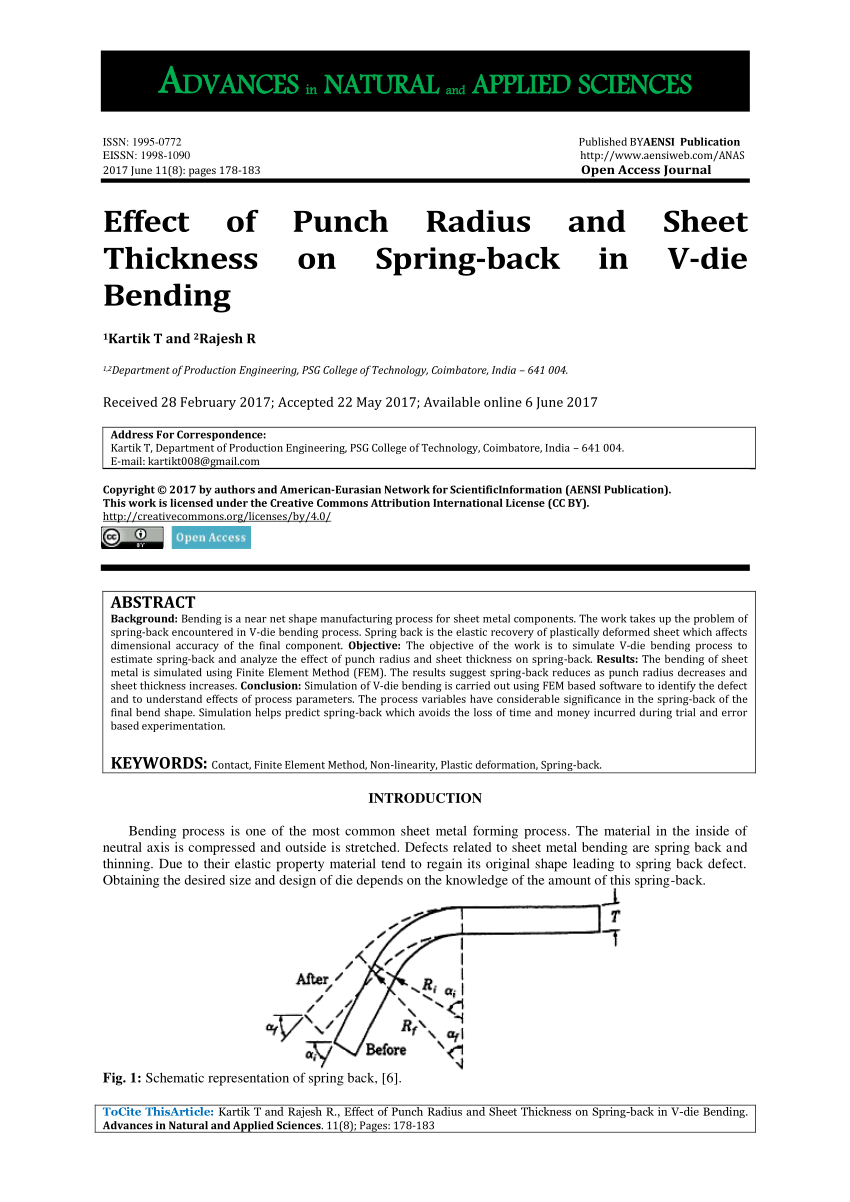

Springback is the geometric change made to a part at the end of the forming process when the part has been released from the forces of the forming tool.

With this method you can get a result anywhere between 90 and 180 degrees.

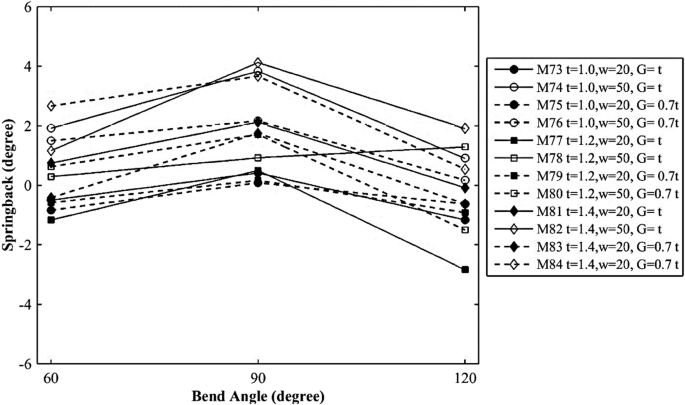

Springback is a semipredictable factor when working with sheet metal.

Though less accurate than bottoming or coining this kind of simplicity is the beauty of the method.

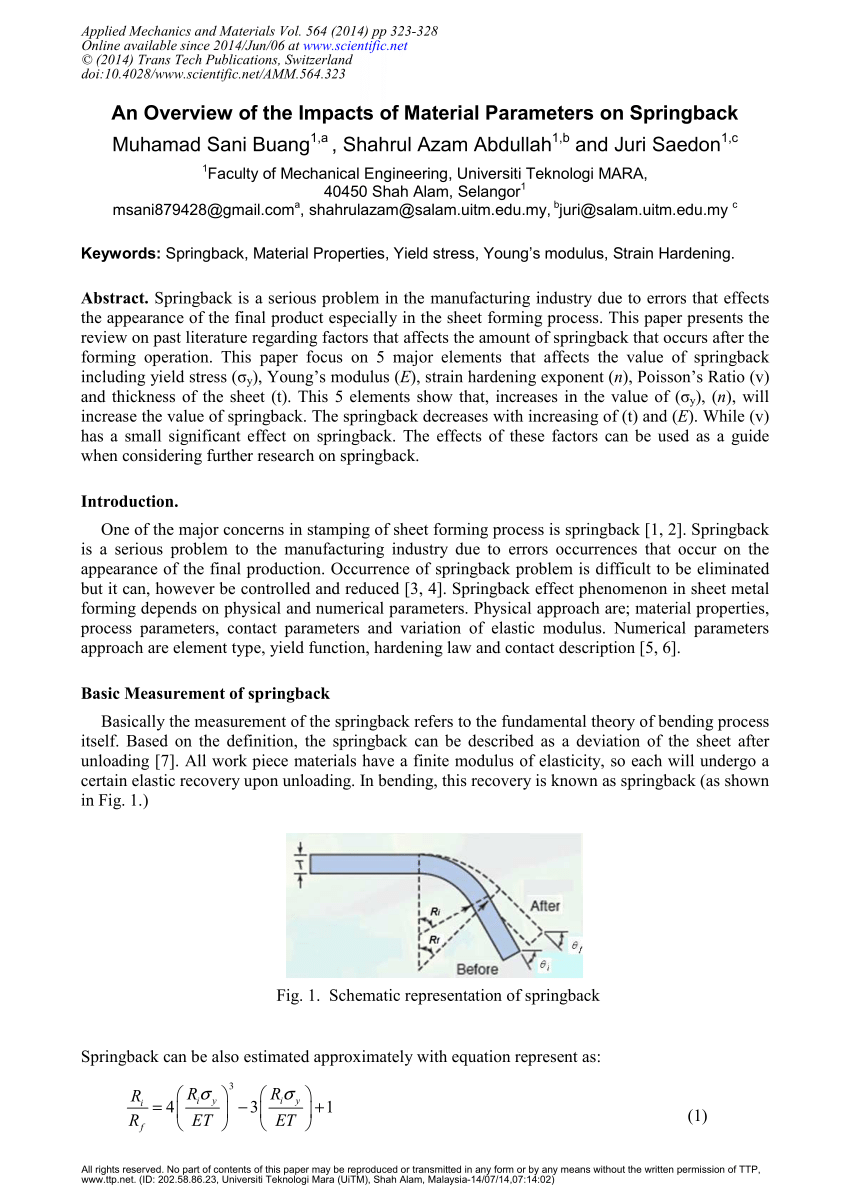

This springback and inside radius calculator estimates the amount of angular change and the relaxing of bend radius that occurs when metal is bent and released from pressure when the proportional limits of a specific material are reached or exceeded the material remains bent figure one.

Due to this elastic recovery it is necessary to over bend the sheet a precise amount to acheive the desired bend radius and bend angle.

Due to the elasticity of sheet metal it tries to get back its previous form before the metal bending and this is how we get springback from sheet metal.

Sheet metal bending can be done using many methods.

Bending springback calculator after a bending operation residual stresses will cause the sheet metal to spring back slightly.

So springback is actually a geometric change that happens to a part of the sheet metal when the metal bending is done and the sheet metal is released from the force of the press brake machine.