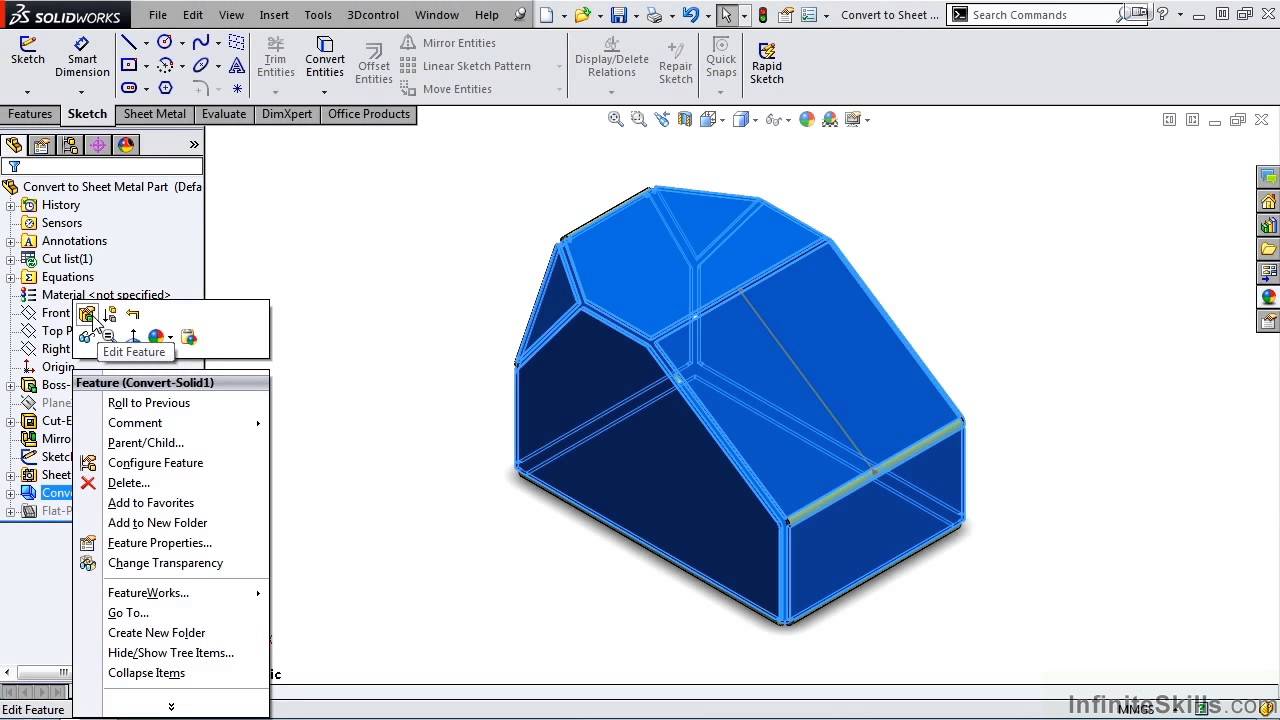

However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal.

Solidworks sheet metal non planar.

Why we re excited about it.

If you can insert an axis the model is an exact cone.

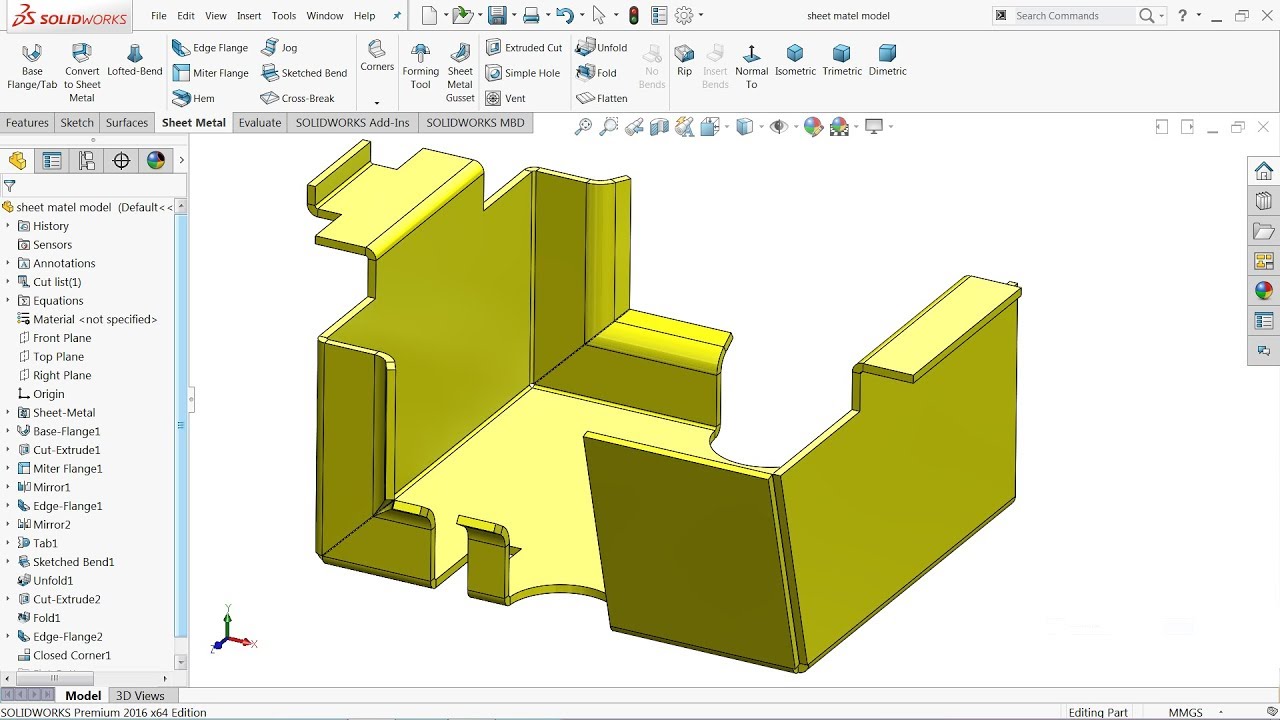

There are specific sheet metal features you can use to create sheet metal bodies quickly.

If you cannot insert an axis then the model is not an exact cone and cannot be unfolded.

Do one of the following.

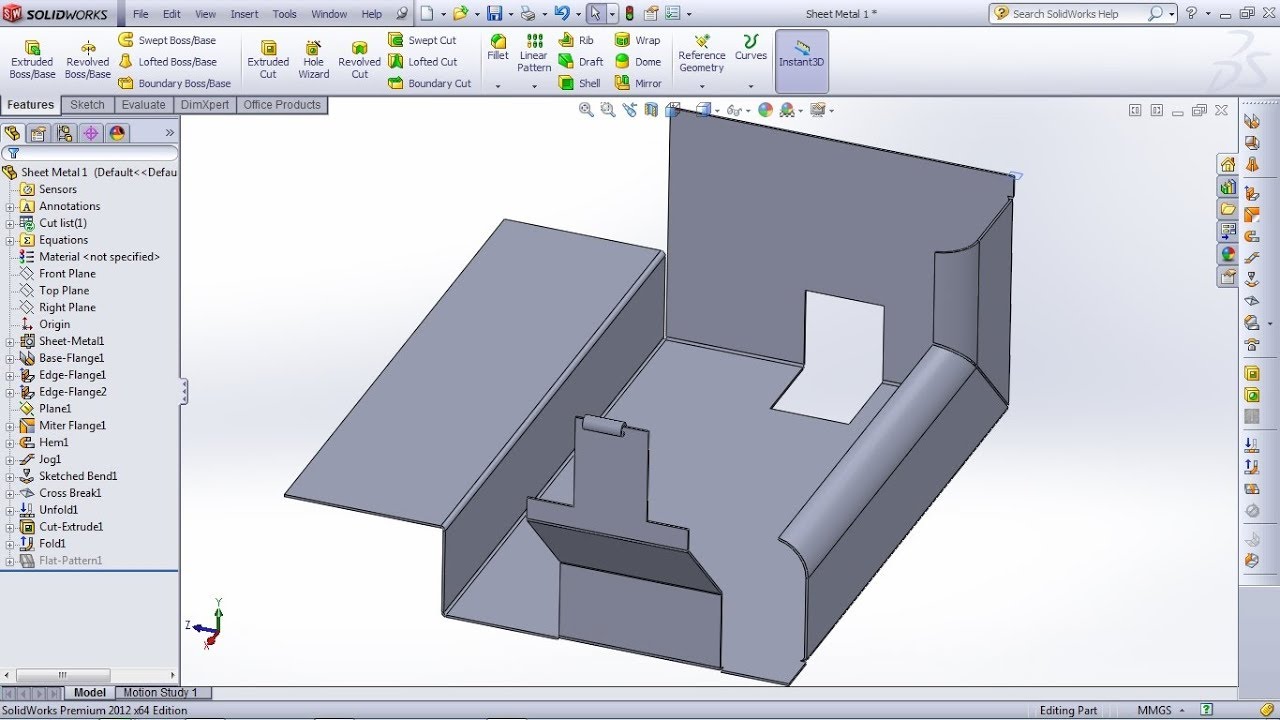

However sheet metal parts created with the lofted bends feature avoid this limitation and unfold appropriately.

As a test try to insert an axis on the conical face.

Solidworks 2019 sp05 to disable web help from within solidworks and use local help instead click help use solidworks web help.

The fixed edge remains in place when the part is flattened.

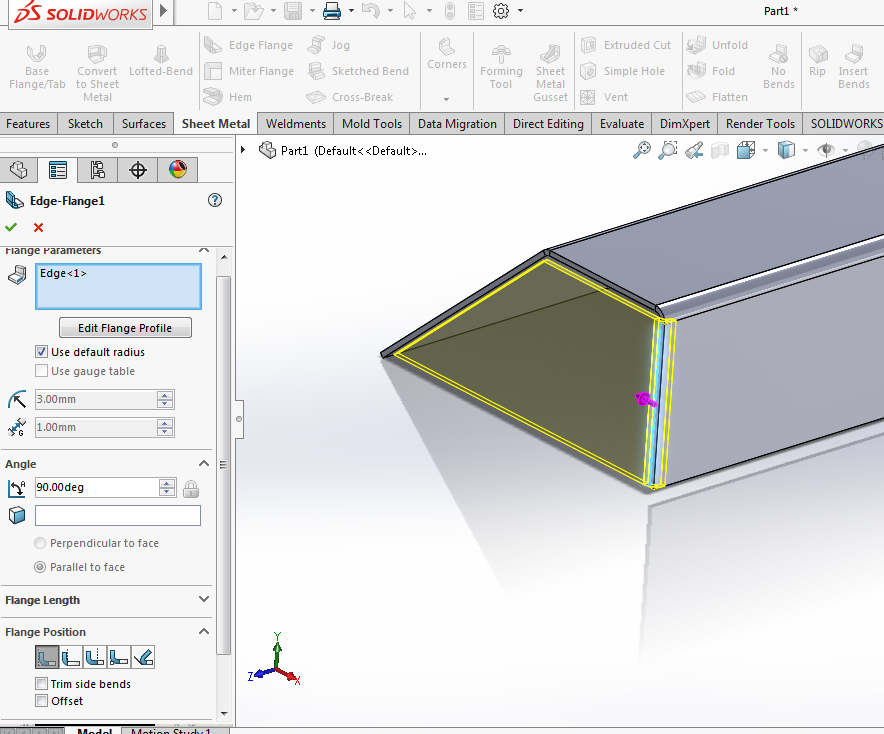

Creating an edge flange along a non planar edge adds a 3d sketch.

You might also like.

Select a planar face tangent to the conical face as the fixed face.

The bends propertymanager appears.

Thickness is linked to the thickness of the sheet metal part.

Click insert bends or insert sheet metal bends.

It further extends the capabilities of sheet metal design to keep up with the dynamic manufacturing capabilities in use by our customers.

In solidworks 2021 edge flange features are now supported on non planar tangent edges of an existing base swept or edge flange.

Exploring options for non planar developable sheetmetal in solidworks joko engineering.