Lofted sheet metal the bend radius is too big for this body question asked by yousif devlin on jul 24 2015 latest reply on nov 7 2019 by naqibullah mohammadullah.

Solidworks sheet metal large radius.

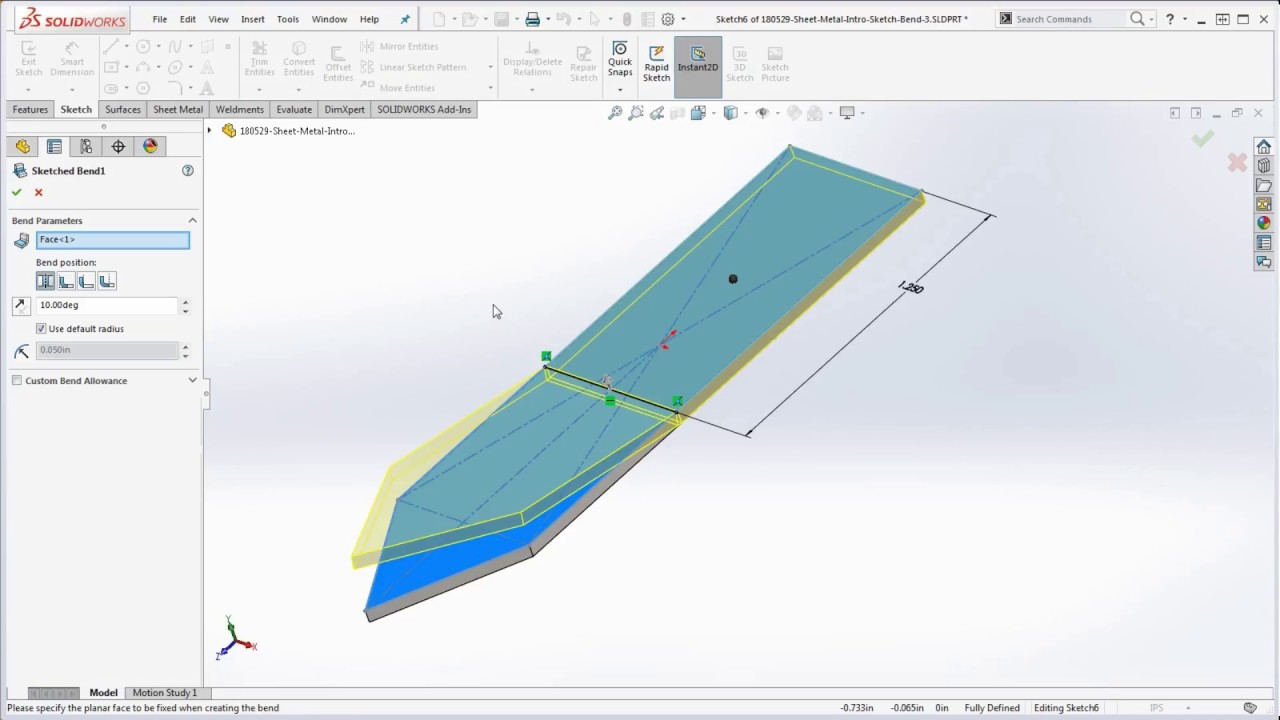

To edit the default bend radius bend allowance or bend deduction or default relief type.

Under sheet metal parameters.

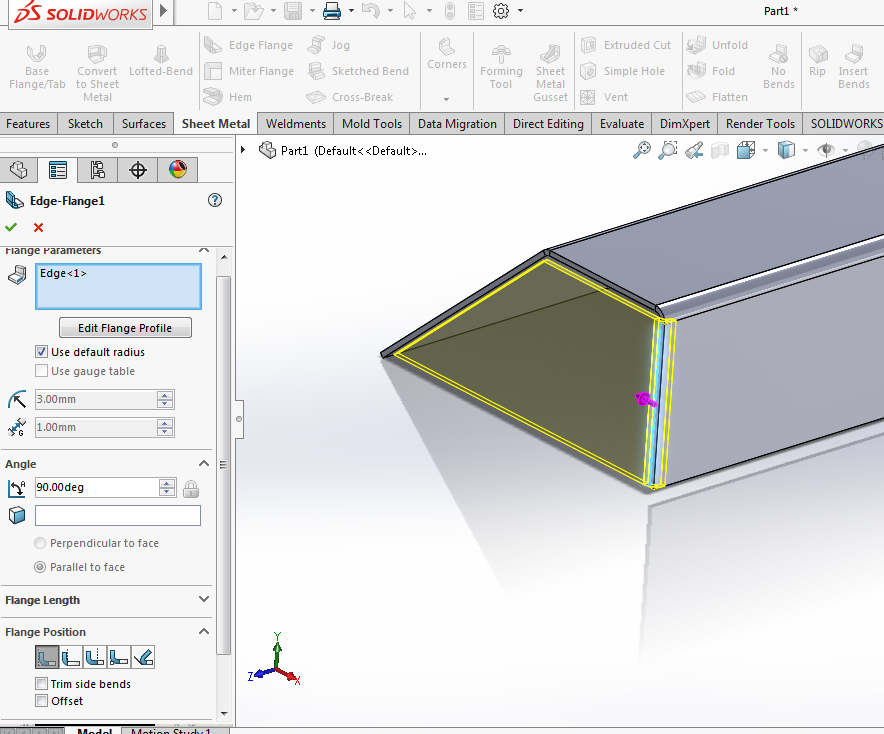

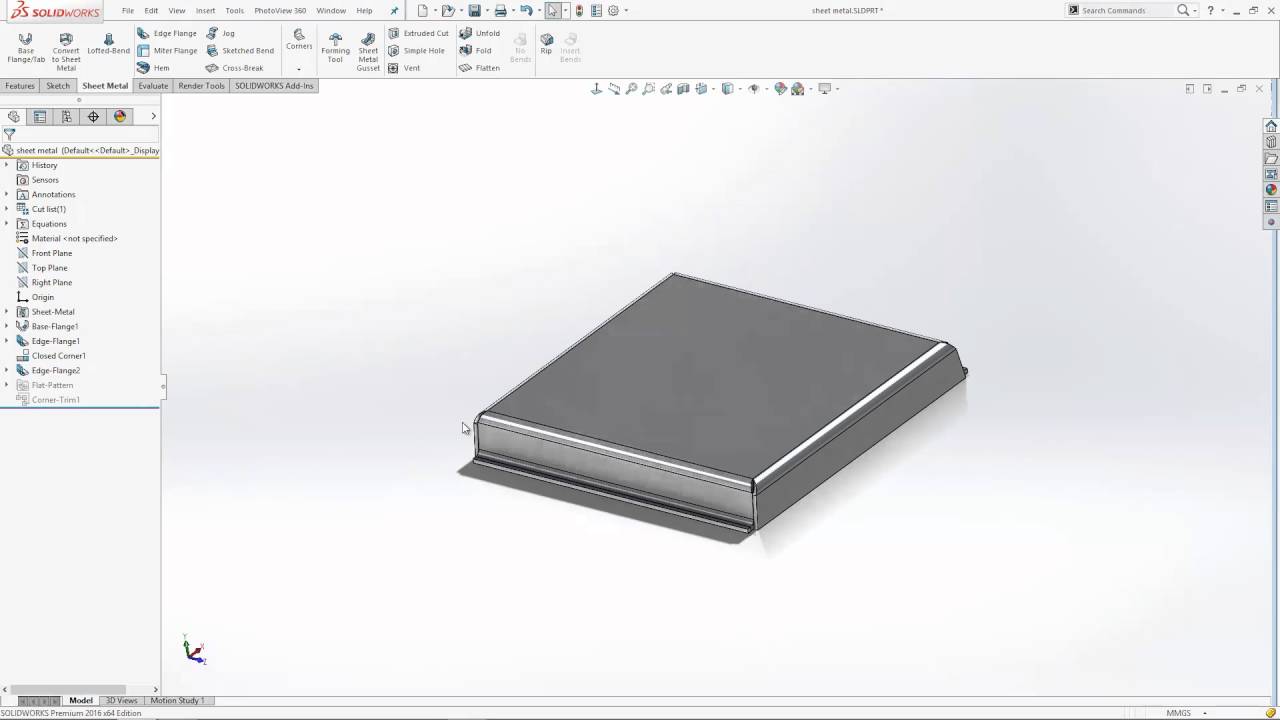

We will focus on the flange method where a sheet metal part is created in the formed state using specialized sheet metal features.

K factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part.

In the new feature s propertymanager clear use default radius and select use gauge table.

When selecting to execute this feature you would get the following options in the dialog box to enter values to create the bump bend lines.

A single table lets you associate a bend allowance bend radius or k factor with any combination of thickness bend radius and material.

Where 0 the length of the part along the inside radius and 1 the length of the part along the outside radius.

Values to enter to create feature.

You can access the sheet metal gauge table from the propertymanager while creating the base flange.

Set the sheet thickness and default bend radius.

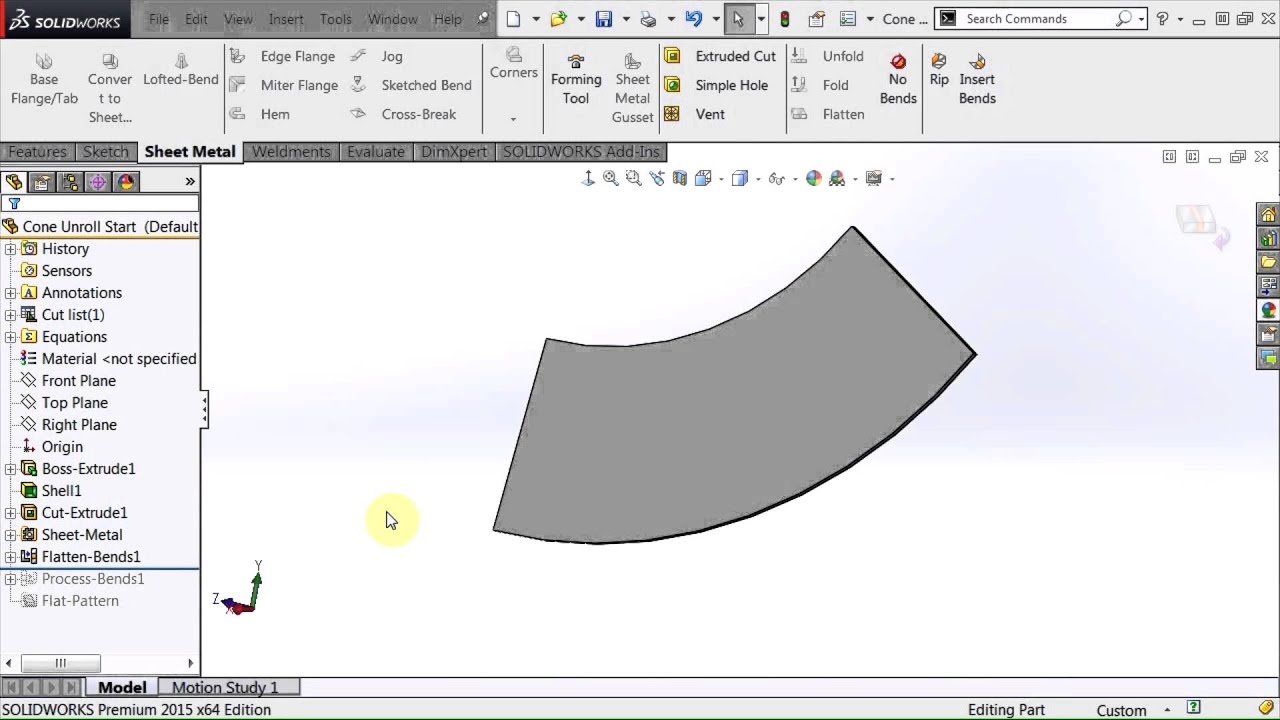

Select keep body if you want to keep the solid body to use in another convert to sheet metal feature.

Sheet metal gauge tables.

Hopefully this can help you troubleshoot some common sheet metal issues going forward.

Select a face as the fixed face for the sheet metal part.

The sheet metal1 feature contains the default bend parameters.

Select another value for the bend radius.

A sheet metal1 feature in the featuremanager design tree indicates a sheet metal part.

If a sheet metal manufacturer does not own a press brake tooling to achieve a large bend radius.

Add another sheet metal feature to the part.

In the base flange propertymanager under sheet metal gauges select use gauge table and then select a table.

Solidworks 3d allows you to quickly create sheet metal part designs using a simple design process saving you time and development costs thanks to specific sheet metal features.